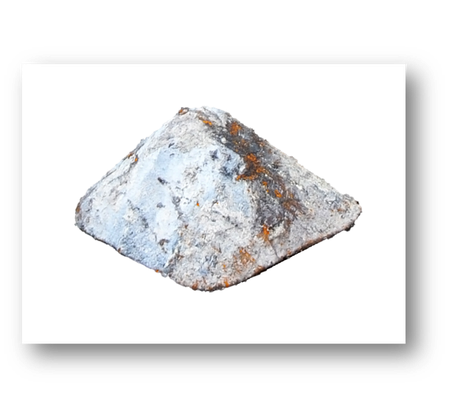

Pig iron is also known as merchant pig iron, which is cast into blocks or ingots. These are then sold to the iron and steel foundry industries in the form of feed stock.

| Name | Application | C (%) | Si (%) | Mn (%) | S (%) | P (%) |

|---|---|---|---|---|---|---|

| Basic Pig Iron | Steel production in EAF | 3.5-4.5 | ≤1.25 | ≤1.0 | ≤0.05 | 0.08-0.15 |

| Foundry/Hematite Pig Iron | Grey iron castings | 3.5-4.1 | 2.5-3.5 | 0.5-1.2 | ≤0.04 | ≤0.12 |

| Nodular/High Purity Pig Iron | Ductile iron castings | 3.7-4.7 | 0.05-1.5 | ≤0.05 | ≤0.025 | ≤0.035 |

Application of relevant Pig Iron types

Basic Pig Iron:

Basic pig iron is used for crude steel production.

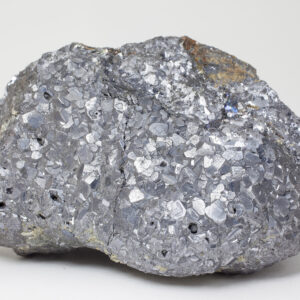

Foundry Pig Iron:

Foundry or hematite pig iron is used by foundries for the production of grey cast iron.

Nodular Pig Iron:

Nodular or high-purity pig iron is used by foundries for the production of ductile iron. Thereby, a low Mn and S content of below 0.6 wt.% and 0.015 wt.% respectively is particularly important.